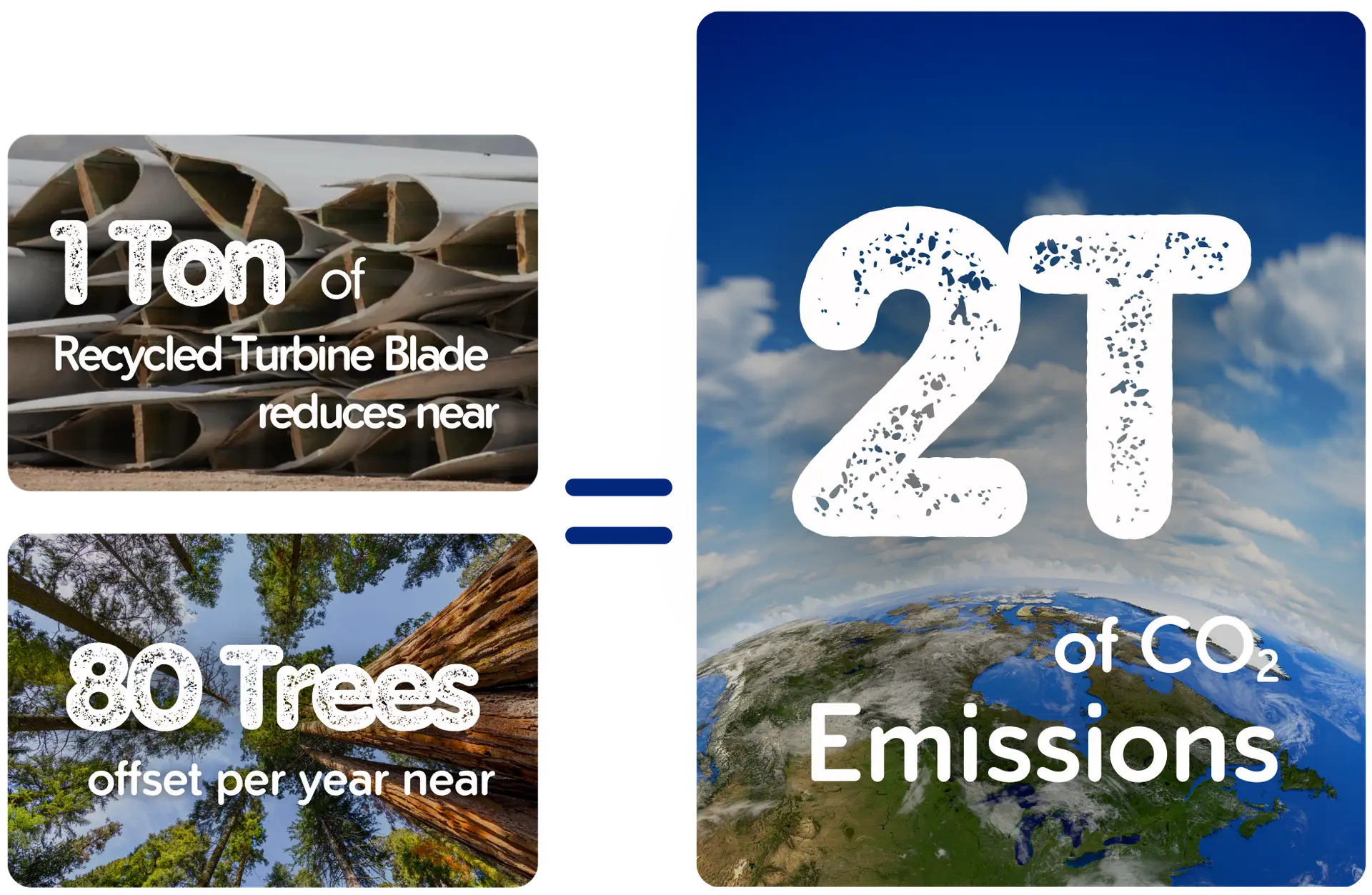

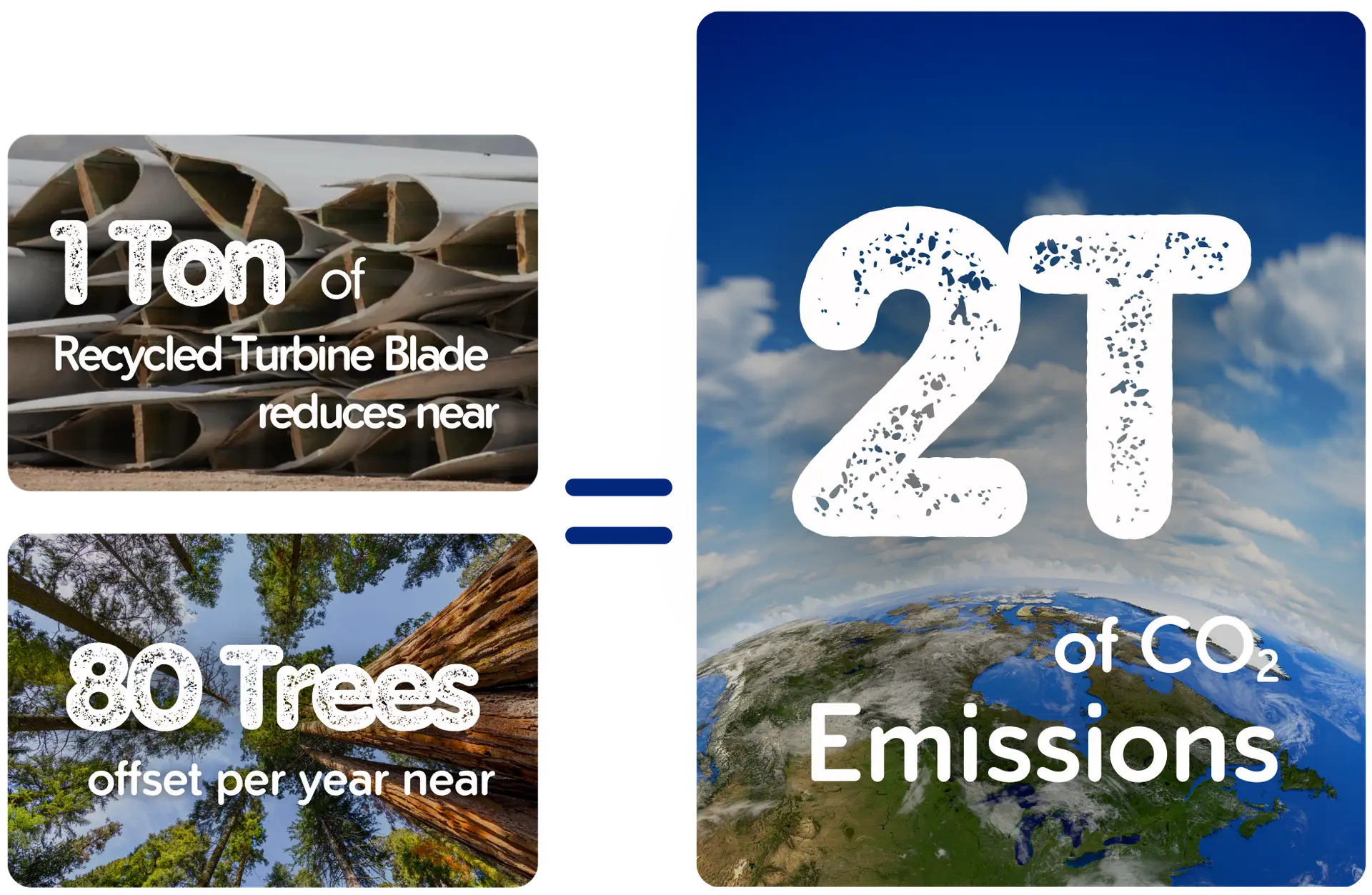

By recycling blades, we not only bolster the circular economy but also enhance the sustainability of the wind industry, foster the development of durable, high-quality products, and minimize our environmental impact.

We offer an alternative solution to keep wind turbine blades out of landfills and away from incineration, creating a win for nature, society, and the economy