We offer an alternative solution to keep wind turbine blades out of landfills and away from incineration, creating a win for nature, society, and the economy.

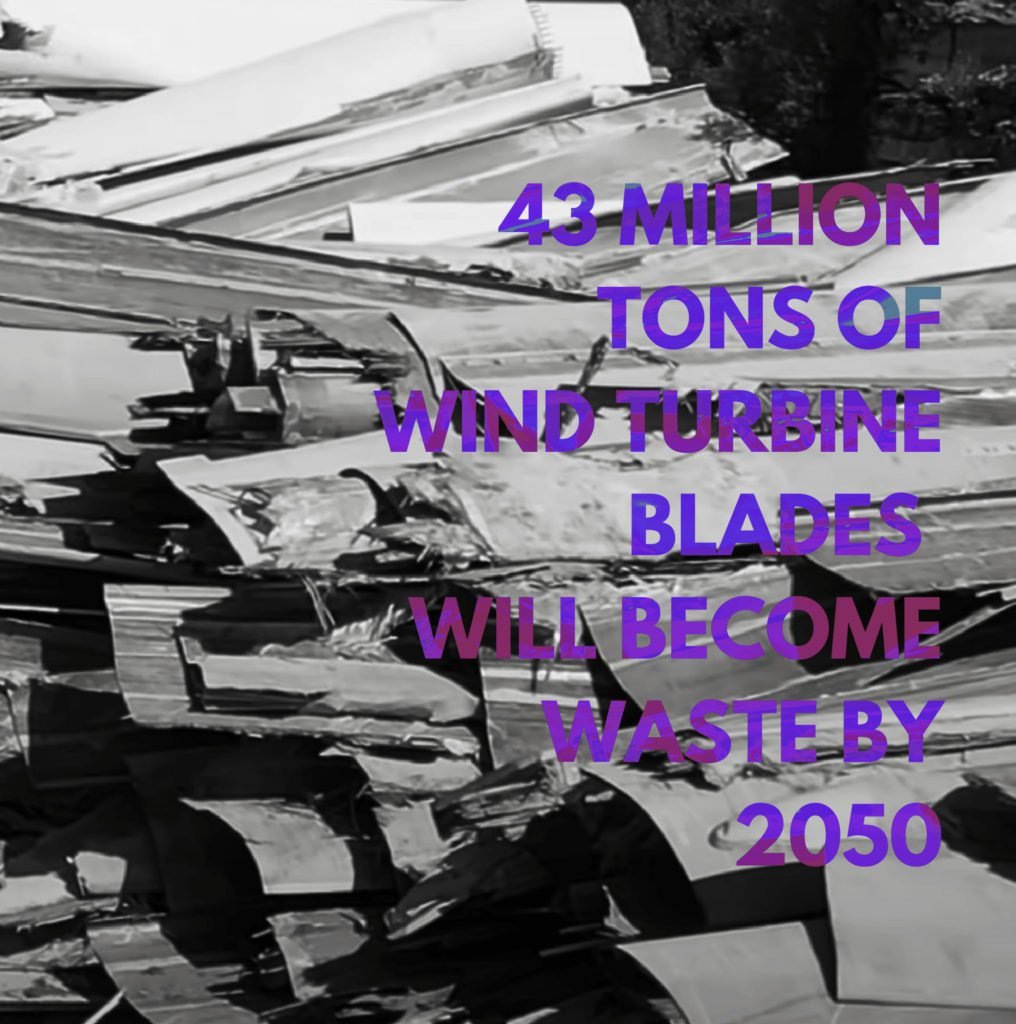

The environmental consequences associated with the wind energy sector, while often unseen, are steadily worsening. As the industry experiences rapid growth, the disposal of wind turbine blades has emerged as a substantial challenge. Presently, the prevailing practice involves sending a large portion of this waste to landfills, which is far from being an environmentally desirable solution. What’s concerning is the escalating rate at which this waste is accumulating, and the data is compelling. Projections indicate that by the year 2050, the global disposal of discarded wind turbine blades will be around 43 million tons. This data underscores the pressing need for sustainable solutions in the wind energy industry to curb this burgeoning issue and reduce its environmental impact.

The problem is just getting worse.

The more companies that adopt our solutions or express interest in collaborating, the faster we can make a positive environmental impact.

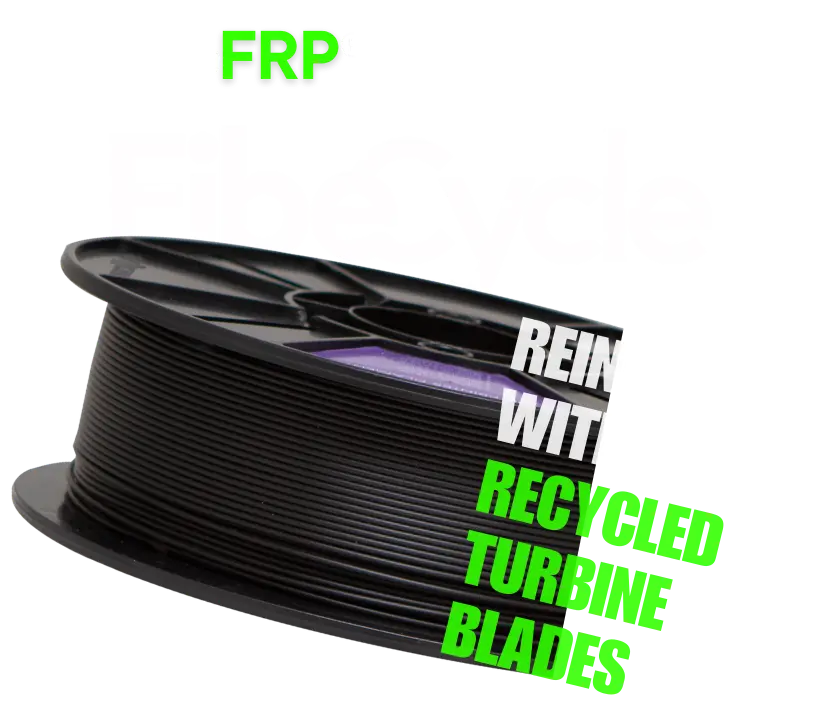

Fiber-Reinforced Polymers (FRP) are widely recognized in the plastics industry for their versatility in creating various products, and can be found in everything from sporting equipment to automotive components.

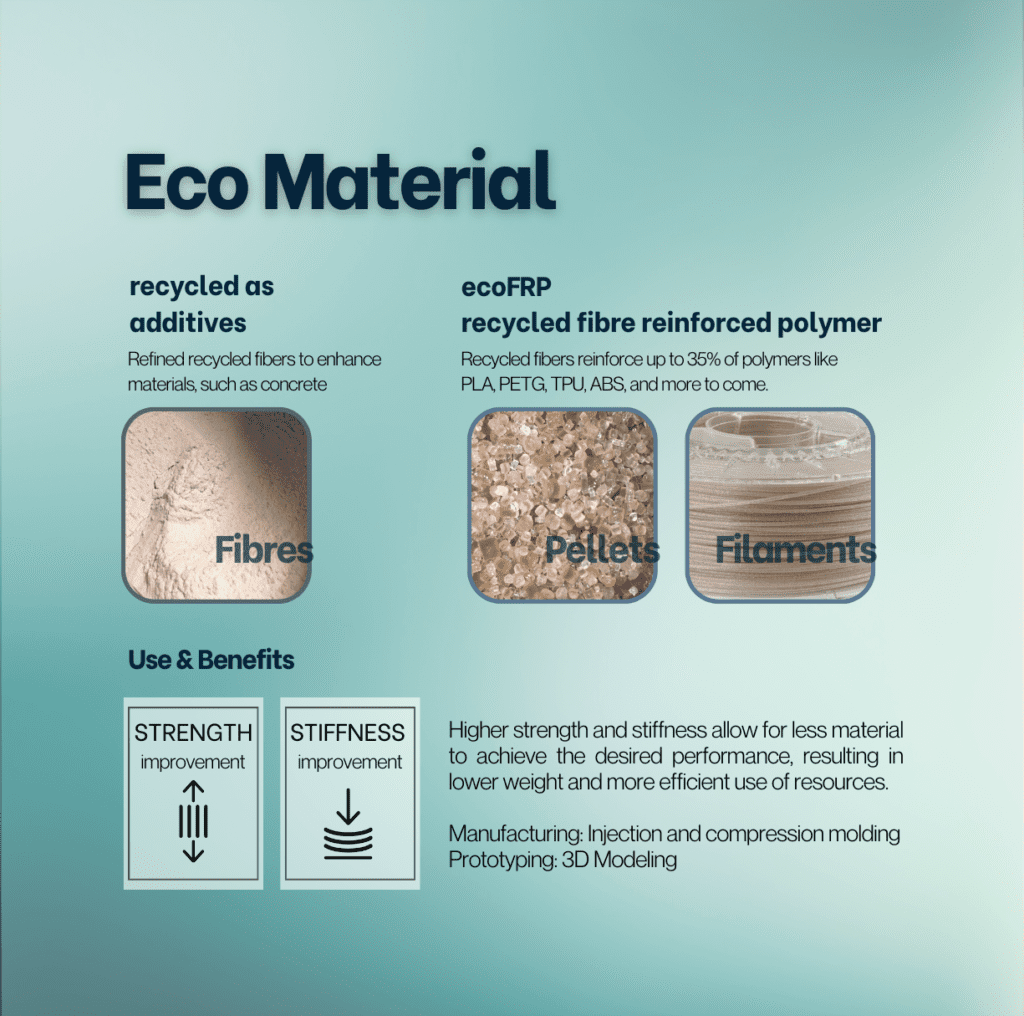

FibeCycle’s ecoFRP lineup, derived from fiberglass artifacts such as end-of-life wind turbine blades, addresses the global demand for eco-friendly materials in sustainable product manufacturing. FibeCycle’s ecoFRP possesses enhanced properties on par with industrial FRP offerings, including improved strength, stiffness, offering a more resource-efficient alternative.

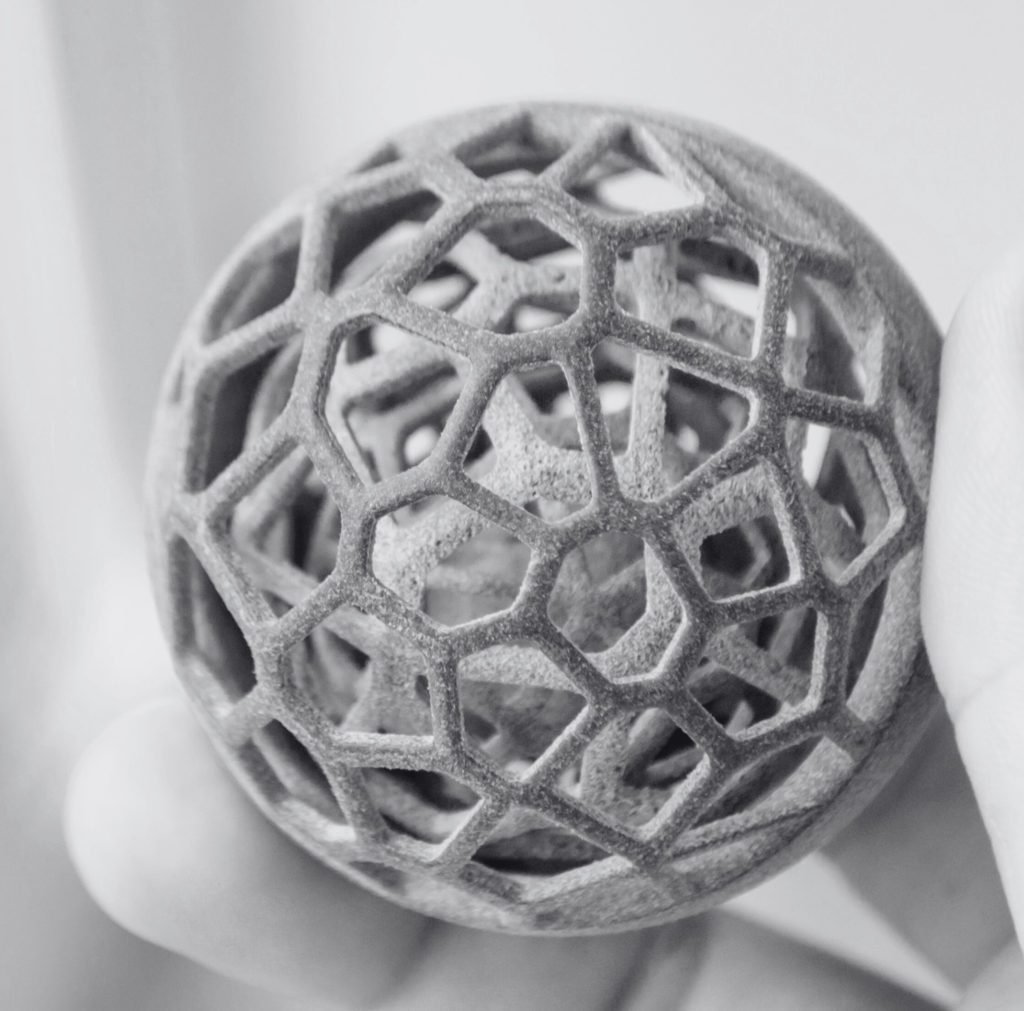

Our offerings include ecoFRP filament for 3D printing and ecoFRP pellets for injection and compression molding.

Additionally, we foster collaborative partnerships with other companies, empowering them by providing our recyclates (refined eco-fiber) for product testing and the co-development of novel sustainable materials.

Our circular approach reduces waste, promotes sustainability, and saves energy and resources by recycling wind turbine blade waste into ecoFRP (Eco-Friendly Fiber-Reinforced Polymers).

Each tonne of recycled blade reduces approximately 1.5 tonnes of CO2 emissions, contributing to climate change mitigation. Capturing just 1% of the estimated blade waste would result in a cumulative carbon removal of 65 Megatonnes of CO2 over the next 27 years. However, we envision even greater growth and impact as others join our mission and help expand our initiatives.