As a Founder and Research Advisor of FibeCycle, my role is steeped in the pursuit of continuous innovation.

I am committed to guiding our team through unexplored avenues, fostering a culture of creativity and significant advancements in our field.

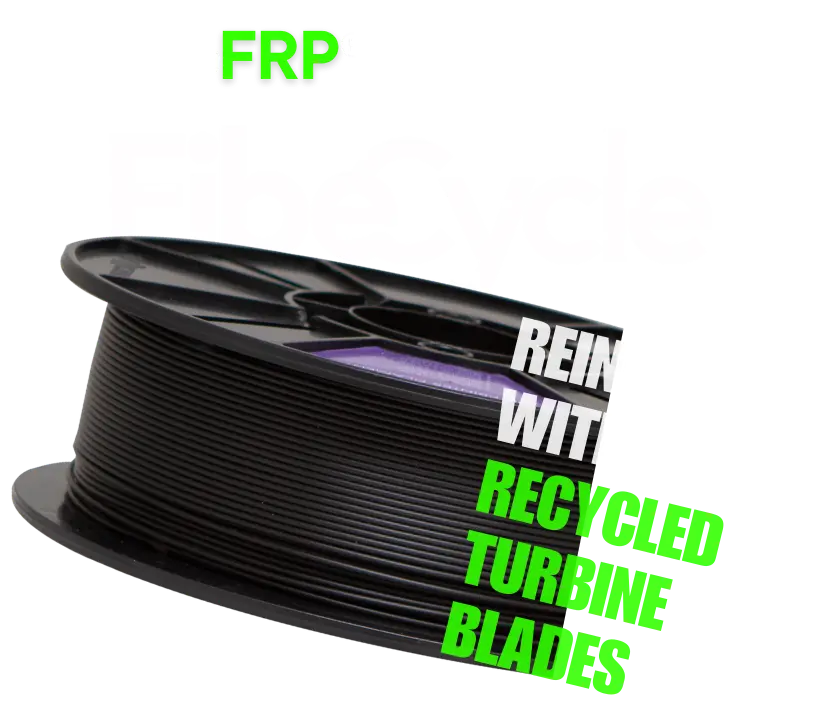

My career in academia and industry has been focused on advanced manufacturing processes, particularly 3D printing. This technology not only reduces materials waste during production but our research has also shown its ability to transform recyclates into stronger products. This was our ‘aha’ moment.

I get excited by solving real-life problems, and at Fibecycle, we’re bridging the gap between innovative research and real-world applications.